ABOUT ENERTECH TECHNOLOGY

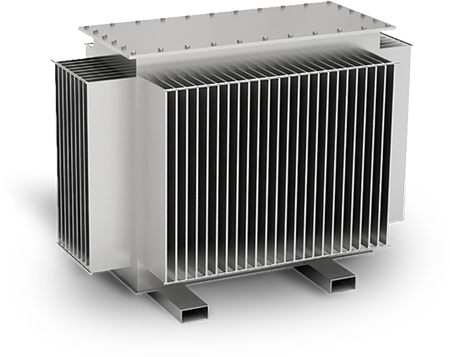

Enertech Technology has come into existence to fill the void in the market of quality corrugated wall panels / fin walls for Transformers tanks and complate Corrugated Transformer Tanks upto 10 MVA. Enertech is also engaged to Repair and service of Distribution Transformers upto 500 KVA. A group of Technocrats with vast experience in this field have got together as a team and supply this much needed product. Based out of The Transformer Hub state of Gujarat, and industrial city of vadodara, the company aspires toserve not just the Stalwarts of these industry in india, but create the main supplier baseacross the world.

Corrugated wall Panels / Fin walls

Key Features of Corrugated Transformer Tank

>30%

Potential for saving in material

>30%

Reduction in the weightof the transformer

>30%

Reduction in the overall volumetric dimension

Strong construction & smaller footprint

No blockage of oil flow into the fins

High efficiency cooling

Improved heat dissipation

Oil cleaning is easier & economic

Less oil & les steel required

The role of fin walls is to increase the surface area in contact with cooling air. Due to the temperature rise of the winding under load, the oil temperature also rises. The hot oil rises upward to the top cover and goes down into the fins where it is cooled by the air rising up between the fins. Hence the heat dissipation becomes faster.

Thus, MS corrugated wall panels / fin walls have eliminated the use of radiators which were a part of traditional transformers tanks, as the fin walls acts as an excellent Heat Exchanger. Following are the key features of courrugated transformer tanks:

-

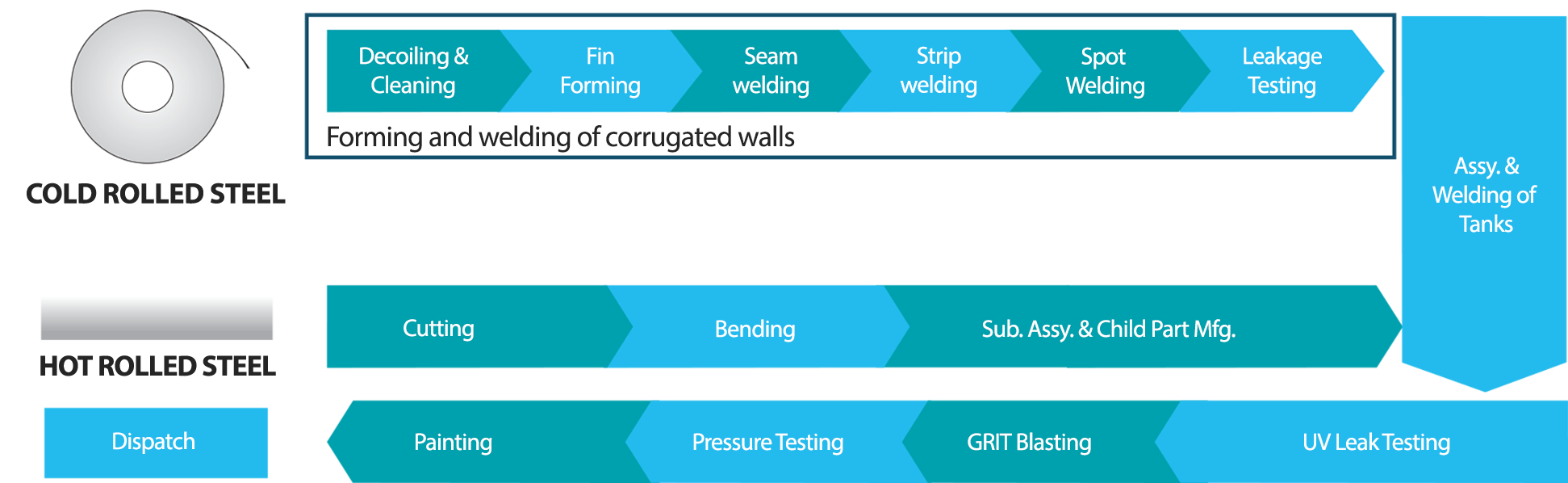

The corrugated fins are manufactures using a special cold rolled MS coil and are directly welded to form the transformer tank.

-

These fins have sufficient degree of elasticity to absorb expansion in volume of the liquid(insulation oil) and it also provides a large surface area to dissipate the heat generated.

-

Transformers with corrugated walls are compact compared to transformers with radiators, thus reducting the space for instalation.

-

The corrugated fin walls with vertical embossed channels provide greater stabillity to the corrugated fin walls.

-

The numbers of welded joints are reduced, thereby, reducing the chances of leakages and also production time.

-

The Transportation cost is lower due to reduction in weight and overall dimensions.

-

It enhances aesthetic appeal compared to the traditional transformer tank.

The Production Line of Corrugated Tanks

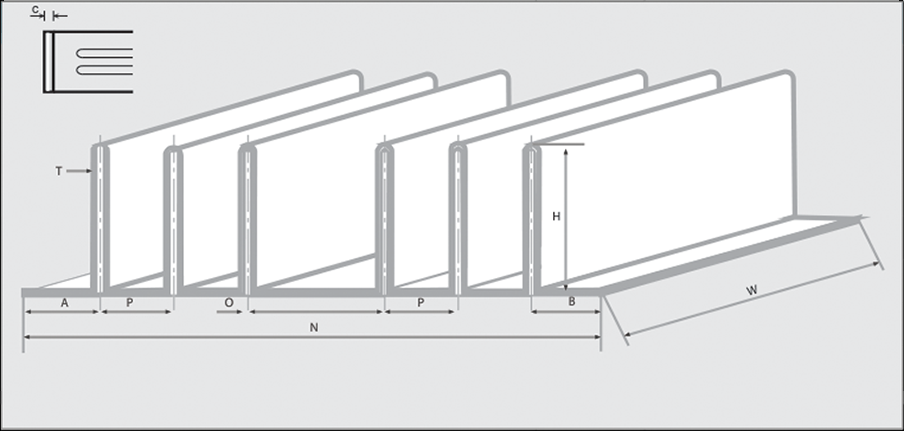

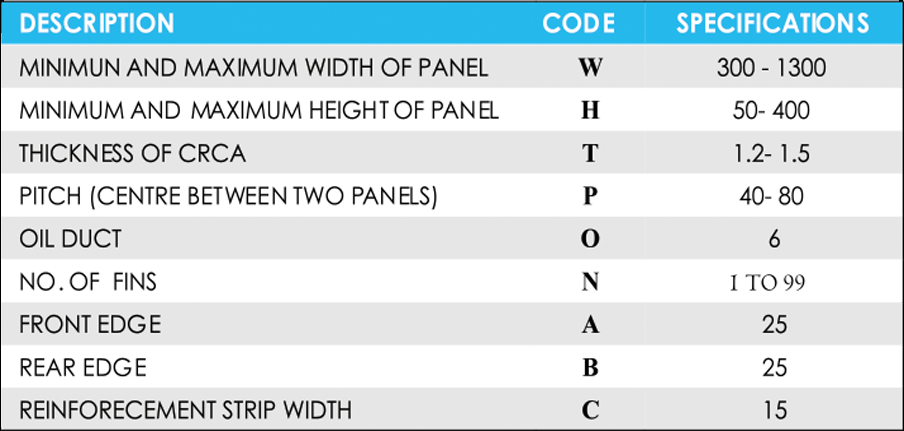

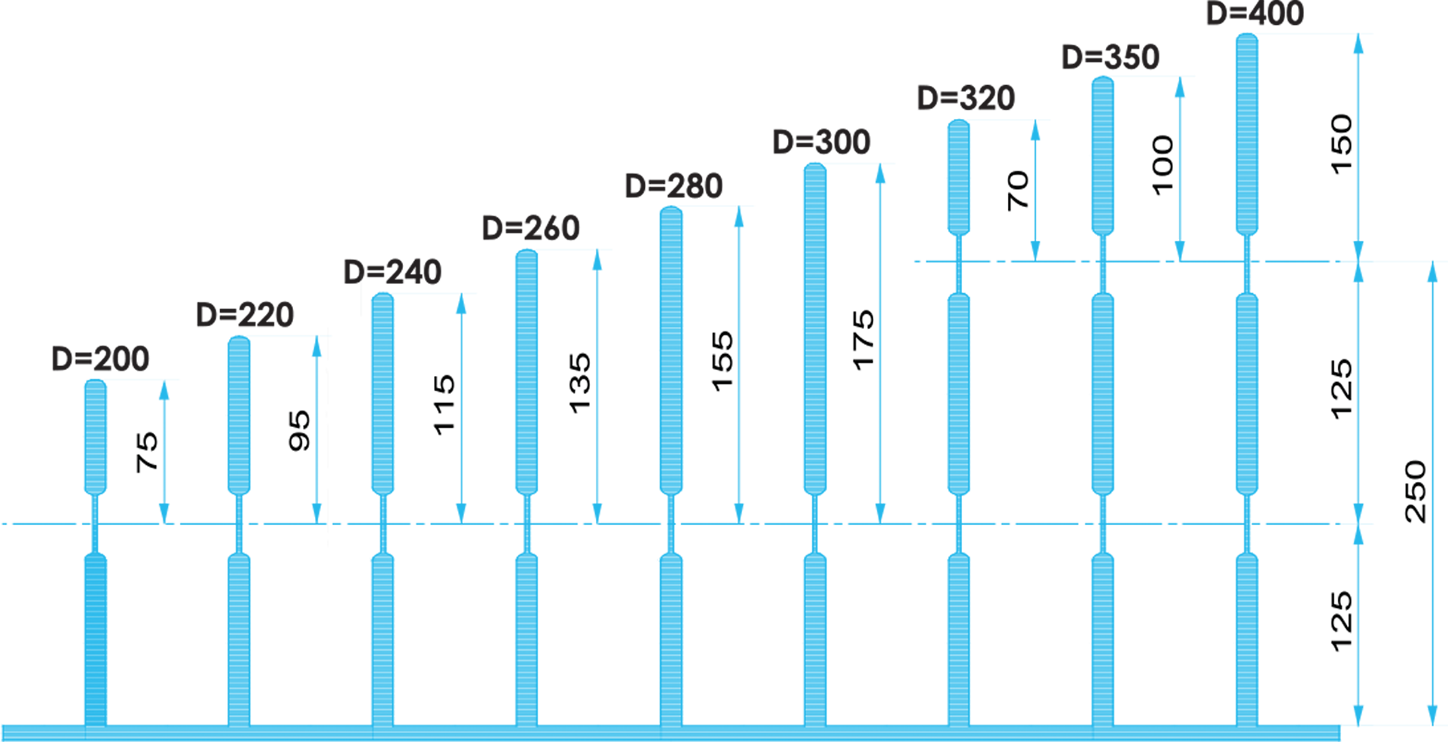

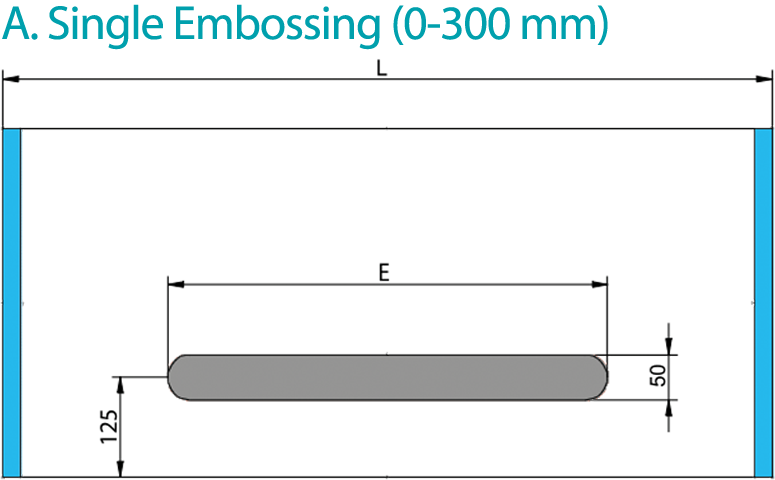

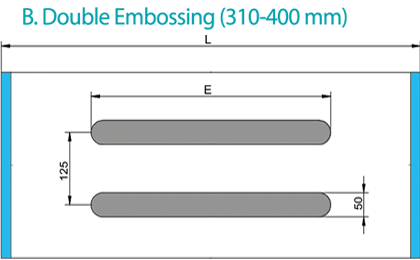

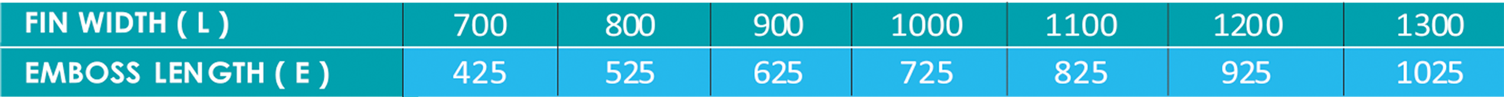

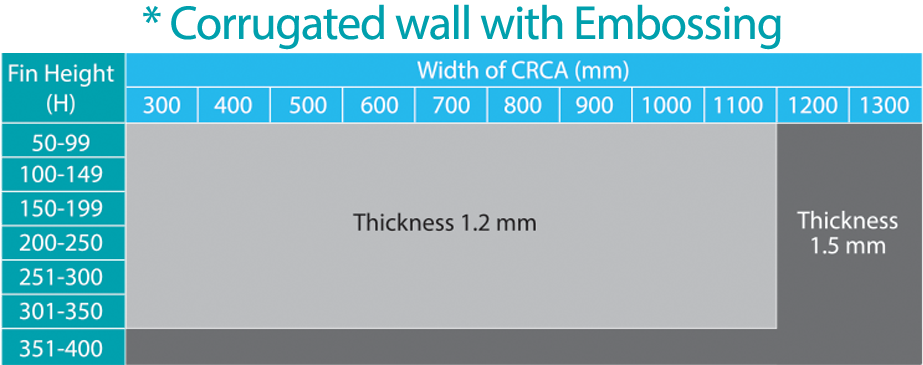

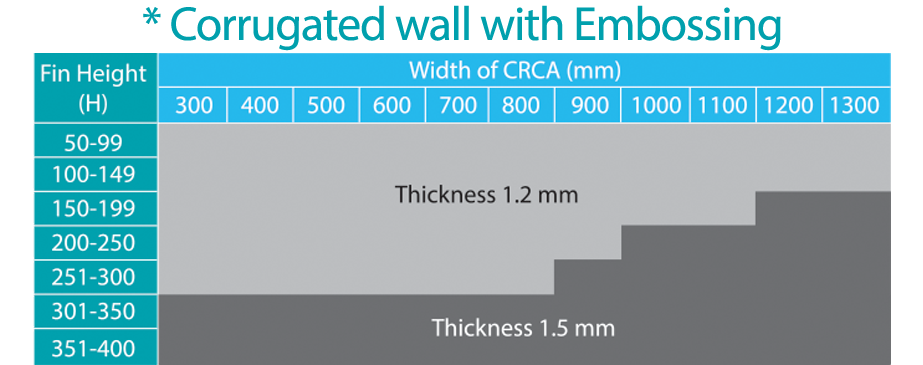

Technical Details for Corrugated wall Panels / Fin walls * Corrugated wall with Embossing

* All Dimensions are in mm

* Position Of Embossing

* Position Of Embossing Length

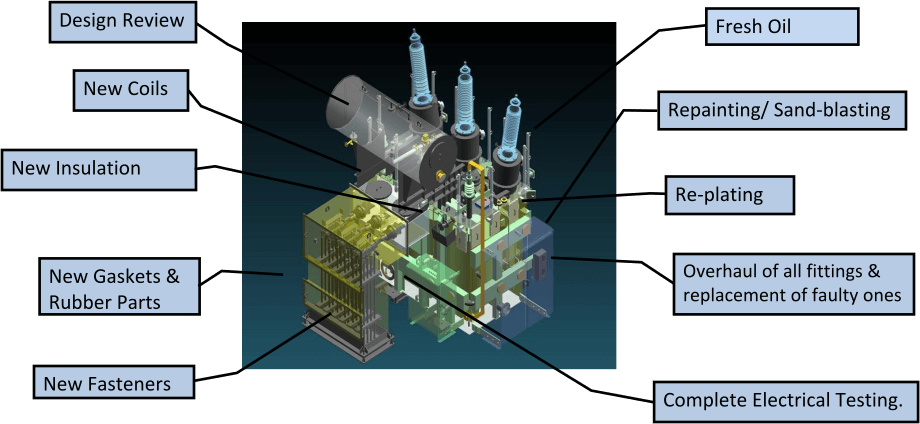

Transformer Repairs & Services

We produce one of the finest & beautiful transformers taking meticulous care with a series of pre & post testing carried out. Our products are designed precisely as per the customer specific requirement and provide good Service for transformer Repairs.

Transformer Repair: Domestic purpose & Small Industry applications.

We offer effective emergency repairing services for correcting faults or failures faced by our end users that include power transformer repair, transformer repair services, etc. Also to meet the contingency, we make sure in providing prompt repair services and spares to replace the obsolete parts of the transformer. To meet the urgent requirements, we offer our clients with transformers to replace the faulty ones for a nominal rent.

We offer transformer repairing services, which include transformer oil filtration and high tension repairing. These services offered by us are unmatched and reliable. To ensure speedy and efficient services, we have a team of technicians who ensure that the fault is repaired immediately.

We produce a wide range for Repairing of distribution transformers (wound core and stack core transformers) starting from 5 KVA to 500 KVA of the voltage class 11kv/433v.

We repair and handle reengineering of the damaged transformers. The repairing services offered to our customer, ensures transformers with high working frequency and power output, reliable service life, high performance standards and low maintenance.

Transformers are designed to have a long life but due to inadequate protection and maintenance of the system, these equipment get damaged. Transformer repairs deals with oil filtration and racemization of transformers, overhauling, distribution transformer repairs etc.

We provide well versed equipment to provide overhauling process. This service can also be personalized as per the requirement and specification of the customers. The overhauling process is highly required to enhance the life of the Transformers

Repair & Rewinding of all kind of Transformers up to 500 KVA at our factory. All the servicing is done by our team of qualified professionals. Well versed with complete wiring and good technical ideas our team executes each project with great ability and precision.

Careers

We are always looking for young and talented professionals from all backgrounds. We are an opportunity employer and take our social responsibilities seriously. The dedication and commitment of our people is fundamental to the progress and success of our business.

We are regularly in need of professionals for the following positions.

Technical

- Production/Fabrication Engineers

- Quality Control Managers

- Workshop Supervisors (Machine Operations, Cutting and Bending, Fitting, Welding, Leakage Testing)

Commercial

- Finance and Accounts Managers

- Marketing Managers

- Administration Managers

If you think you are a perfect match for any of the above posts, please submit your CV to:

[email protected]Registered office and plant

Contact Us